Foiling

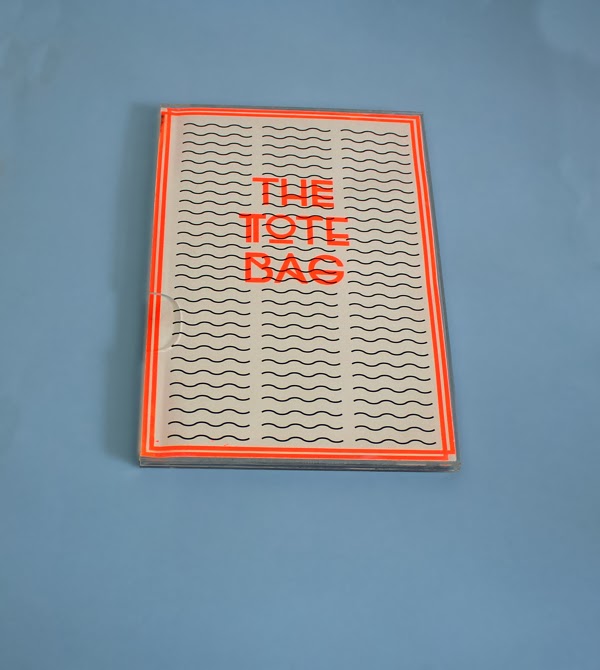

Foil stamping, typically a commercial print process, is the application of pigment or metallic foil, often gold or silver , but can also be various patterns or what is known as pastel foil which is a flat opaque colour or white special film-backed material, to paper where a heated die is stamped onto the foil, making it adhere to the surface leaving the design of the die on the paper. Foil stamping can be combined with embossing to create a more striking 3D image.

Foil stamping machines, also known as hot foil stampers, use heat to transfer metallic foil to a solid surface. Examples of items that are foil stamped include pencils, napkins, matchbooks, photographs and books. The foil stamp is a permanent process. These machines are popular with wedding businesses, photography studios and other businesses that need to brand or mark products.

Spot Varnish

On to paper:

Ultra-violet cured coatings can be applied over ink printed on paper and dried by exposure to UV radiation. UV coatings can be formulated up to 100% solids so that they have no volatile component that contributes to pollution. This high solids level also allows for the coating to be applied in very thin films. UV coatings can be formulated to a wide variety of gloss ranges. UV coating can be applied via most conventional industrial coating applications as well as by silkscreen.

Due to the normally high solids content of UV coating/varnish the surface of the cured film can be extremely reflective and glossy. 80 lb text and heavier weights of paper can be UV coated, however, cover weights are preferred.

UV can be applied on spot locations of the paper or by flooding the page. This coating application can deepen the colour of the printed area.

A printed page with UV coating applied can be very shiny or flattened to a matte finish. A good example of UV coated paper is photo paper sold for home printing projects. UV coatings that are not fully cured can have a slightly sticky feeling.

On to glass/plastic:

Glass and plastic can be coated to diminish the amount of ultraviolet radiation that passes through. Common uses of such coating include eyeglasses and automotive windows. Photographic filters remove ultraviolet to prevent exposure of the film or sensor by invisible light. UV curable coatings can be used to impart a variety of properties to polymeric surfaces, including glare reduction, wear or scratch resistance, anti-fogging, microbial resistance, chemical resistance. Computer screens, keyboards, and most other personal electronic devices are treated with some type of UV-curable coating. Coatings are usually applied to plastic substrates via spray, dip, roll, flow and other processes. UV-curable coatings are often specified for plastic parts because the process does not require heat, which can distort the plastic shape.

Embossing

Embossing and debossing are the processes of creating either raised or recessed relief images and designs in paper and other materials. An embossed pattern is raised against the background, while a debossed pattern is sunken into the surface of the material (but might protrude somewhat on the reverse, back side).

Blind emboss

Blind embossing does not include the use of ink or foil to highlight the embossed area. The change in the dimensional appearance of the material is the only noticeable difference resulting from the embossing. The blind embossing process provides a clean and distinctive or subtle image on paper stock. It is best used to create a subtle impression or low level of attention to the piece, yet provide some slight form of differentiation for the finished work.

Registered emboss

Registered embossing is a process that places the embossed image in alignment with another element created with ink, foil, punching, or with a second embossed image.

Combination emboss

Combination embossing is the process of embossing and foil stamping the same image. It involves imprinting and aligning foil over an embossed image to create a foil emboss. A sculptured die, generally made of brass is used for this procedure. The process requires close registration that must be controlled to keep the image and foil matched precisely. The process of embossing and foil stamping is accomplished in one operation with the use of a combination die. The combination die has a cutting edge around the perimeter to cleanly break the excess foil away from the embossed area.

Etching

Etching is the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglioin the metal (the original process—in modern manufacturing other chemicals may be used on other types of material). As an intagliomethod of printmaking, it is, along with engraving, the most important technique for old master prints, and remains in wide use today.

Photo etching

Light sensitive polymer plates allow for photorealistic etchings. A photo-sensitive coating is applied to the plate by either the plate supplier or the artist. Light is projected onto the plate as a negative image to expose it. Photopolymer plates are either washed in hot water or under other chemicals according to the plate manufacturers' instructions. Areas of the photo-etch image may be stopped-out before etching to exclude them from the final image on the plate, or removed or lightened by scraping and burnishing once the plate has been etched. Once the photo-etching process is complete, the plate can be worked further as a normal intaglio plate, using drypoint, further etching, engraving, etc. The final result is an intaglio plate which is printed like any other.

Printing

Printing the plate is done by covering the surface with ink, then rubbing the ink off the surface with tarlatan cloth or newsprint, leaving ink in the roughened areas and lines. Damp paper is placed on the plate, and both are run through a printing press; the pressure forces the paper into contact with the ink, transferring the image. Unfortunately, the pressure also subtly degrades the image in the plate, smoothing the roughened areas and closing the lines; a copper plate is good for, at most, a few hundred printings of a strongly etched imaged before the degradation is considered too great by the artist. At that point, the artist can manually restore the plate by re-etching it, essentially putting ground back on and retracing their lines; alternatively, plates can be electro-plated before printing with a harder metal to preserve the surface. Zinc is also used, because as a softer metal, etching times are shorter; however, that softness also leads to faster degradation of the image in the press.

Screen Printing

Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil to receive a desired image. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A fill blade or squeegee is moved across the screen stencil, forcing or pumping ink into the mesh openings for transfer by capillary action during the squeegee stroke. Basically, it is the process of using a stencil to apply ink onto a substrate, whether it be t-shirts, posters, stickers, vinyl, wood, or other material.

Screen printing is also a stencil method of print making in which a design is imposed on a screen of polyester or other fine mesh, with blank areas coated with an impermeable substance. Ink is forced into the mesh openings by the fill blade or squeegee and onto the printing surface during the squeegee stroke. It is also known as silkscreen, serigraphy, and serigraph printing. One colour is printed at a time, so several screens can be used to produce a multicoloured image or design.

No comments:

Post a Comment